Our Vision

To create advanced micro and nano-textured polymer films that enhance and enable new industrial applications, driving innovation across industries.

About us

INMOLD specializes in fabrication of micro-and nano-patterns in polymer surfaces. Our core technology uses a roll-to-roll pattern replication technique to achieve high quality micro- and nano-imprints at high production volumes. Over the years we have collected a broad portfolio of micro and nanostructures and are deeply enthusiastic about extending our expertise to clients seeking the perfect functionality.

Contact us today to learn more about our process and discover how we can help you scale up the production of your macro- and nano-patterns.

Our Story

2007

Founded by Henrik Pranov, Jan Buch Andersen, and Morten Hansen, INMOLD A/S is dedicated to the development of surface coatings and pattern services as its primary areas of focus.

2011

Establishment of a high-throughput replication process for micro and nanostructures based on Roll-to-Roll Extrusion Coating.

2014

Development of a revolutionary heat-generating lens technology and launch of a new company known as Heliac A/S. Heliac specializes in producing, distributing, and installing solar fields that utilize our innovative, cost-effective, and high-efficiency lens technology.

2020

Facility upgrades and adjustment of the Roll-to-Roll process parameter to enable replication of large microstructures in film thicknesses up to 300µm (with particular focus on microfluidic application).

2022

Decpt Aps originated as a spin-off from INMOLD A/S, driven by the mission to advance and leverage nanostructured foil for defense applications, specifically emphasizing thermal and visual shielding capabilities.

Today

We’re based in Nivå and continue our specialization in roll-to-roll technology, exploring various ideas and techniques in our research and development efforts.

Patented Technology — Customized Production — Professional Solution

Our Patented Technology

The technology has significant advantages in comparison competing R2R technologies:

- High Speed production

- Injection molded parts can be replaced with imprinted films

- Allow replication of large area imprint

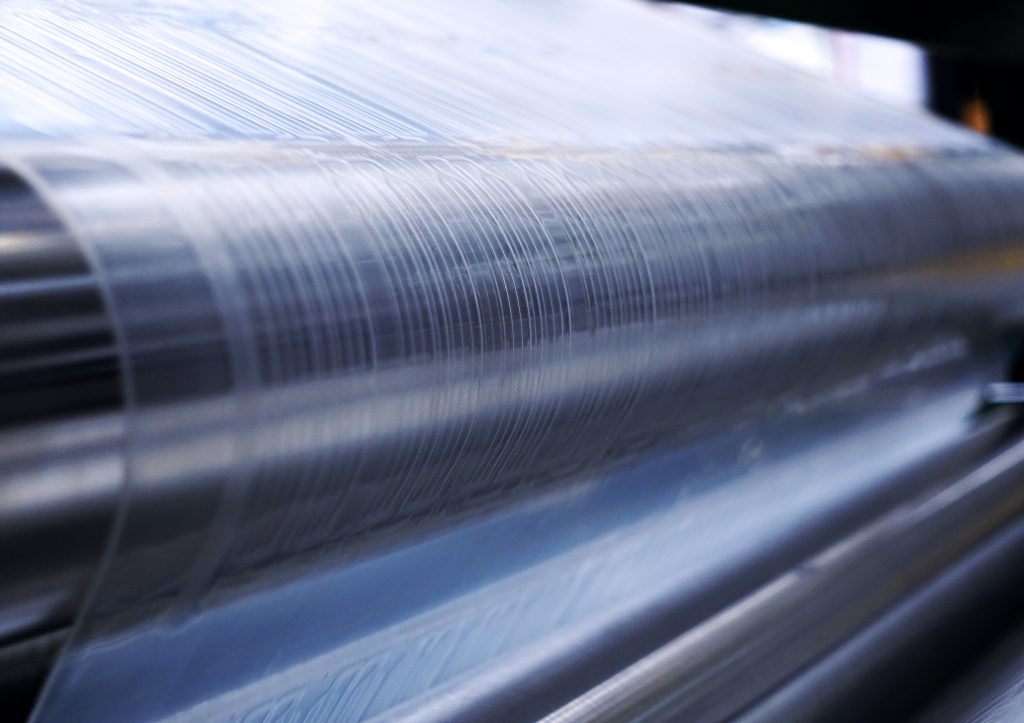

The Roll-to-Roll Platform

Our patented high throughput R2R replication line allows fast replication of customized patterns. fabricated patterns will analysed using inline QC (confocal, microscopy).

The replication platform is based on R2R-Extrusion Coating. Hereby, a curtain of molten thermoplastic polymer is extruded onto a carrier film before entering a nip of a structured cooling roller and a pressurized counter roller. The structures on the cooling roller become instantly imprinted into the hot polymer melt. The film is released as a solidified film.

ISO-Standard Cleanroom

Access to a state-of-the-art class ISO 100 cleanroom offered by DTU Nanolab allows us to offer the fabrication of customized designs (masters) applicable for upscaled replication using our patented high-throughput replication process based on R2R-Extrusion Coating. Our broad knowledge of available cleanroom fabrication techniques combined with polymer replication and characterization methods allows us to offer a range of services.

- E-beam / DUV / UV lithography

- Dry / wet etching processes

- Dry resist processing

- Thin layer deposition

- Laser surface texturing

- SEM, profilometry, microscopy

Explore our current and previous projects

created in partnership with our esteemed partners